Zogulitsa

Tungsten Solid Carbide Ndodo

Carbide Rods Kufotokozera

Ndodo za Tungsten carbide zimagwiritsidwa ntchito kwambiri popanga zida zolimba za carbide, monga mphero, kubowola, reamers, odula mphero, kupondaponda, ndi zida zoyezera m'mafakitale osiyanasiyana.Kedel Tool imapanga ndodo zapamwamba komanso zosagwirizana za carbide m'makalasi osiyanasiyana kuphatikiza K20F, K25F, ndi zina zambiri. Kusankhidwa kokwanira kwa ndodo za tungsten carbide miyeso yosiyanasiyana kulipo, ndipo timaperekanso ntchito zosintha makonda malinga ndi zomwe mukufuna. Monga wopanga ISO, Kedeltool amagwiritsa ntchito zida zapamwamba kwambiri kuti zitsimikizire mtundu ndi magwiridwe antchito a ndodo zathu za carbide. Ndi kuyang'anitsitsa kwabwino kwambiri, titha kuwonetsetsa kuti zinthu zili bwino mkati mwa gulu lililonse.

Mitundu ya Kedel Carbide Rod

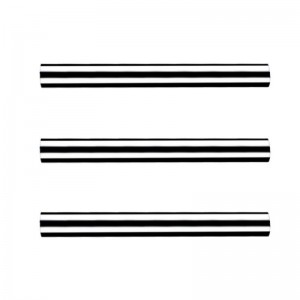

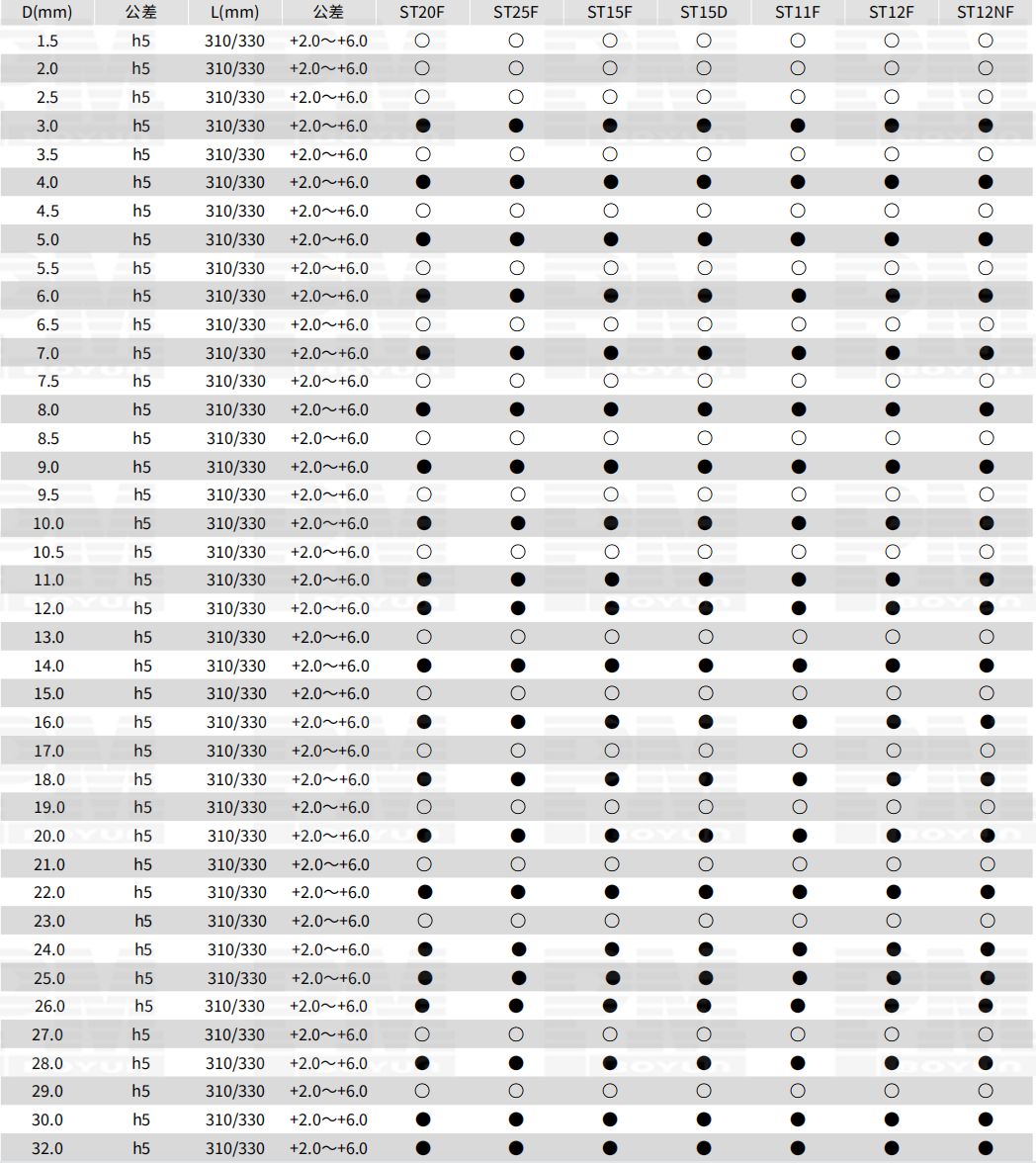

1. Ndodo Zolimba za Carbide mu Metrics

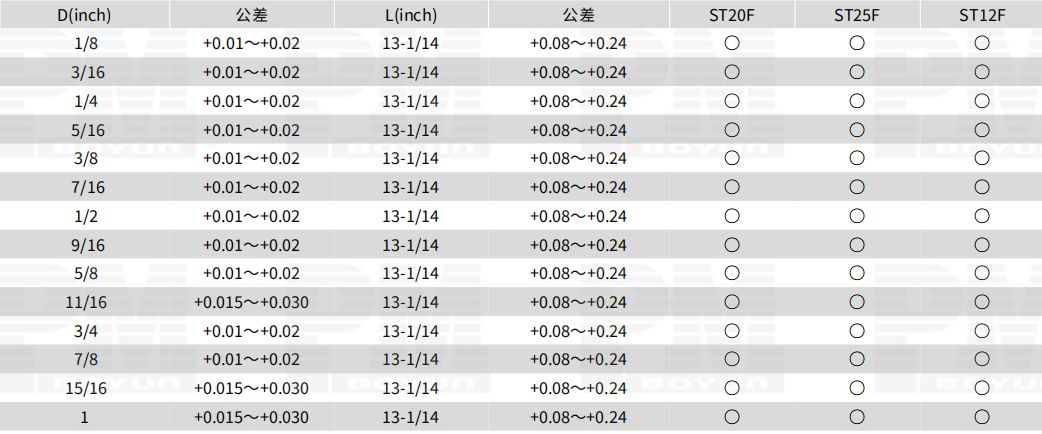

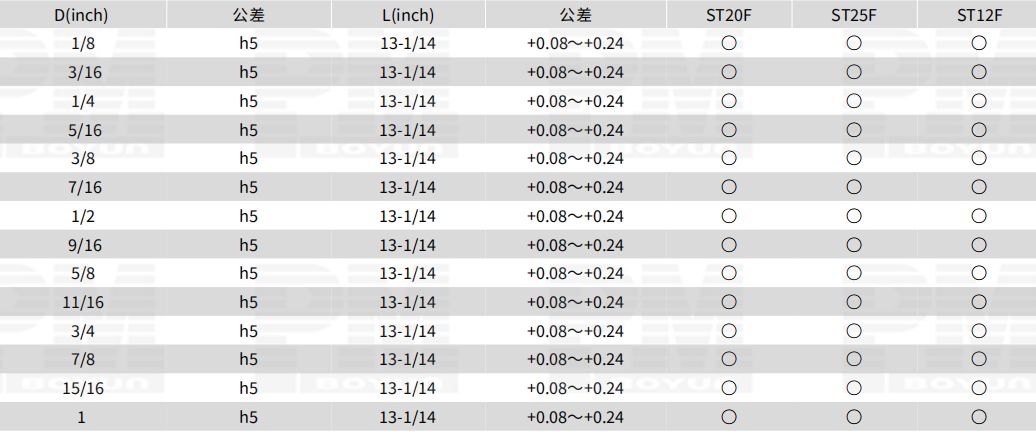

2. Ndodo Zolimba za Carbide mu mainchesi

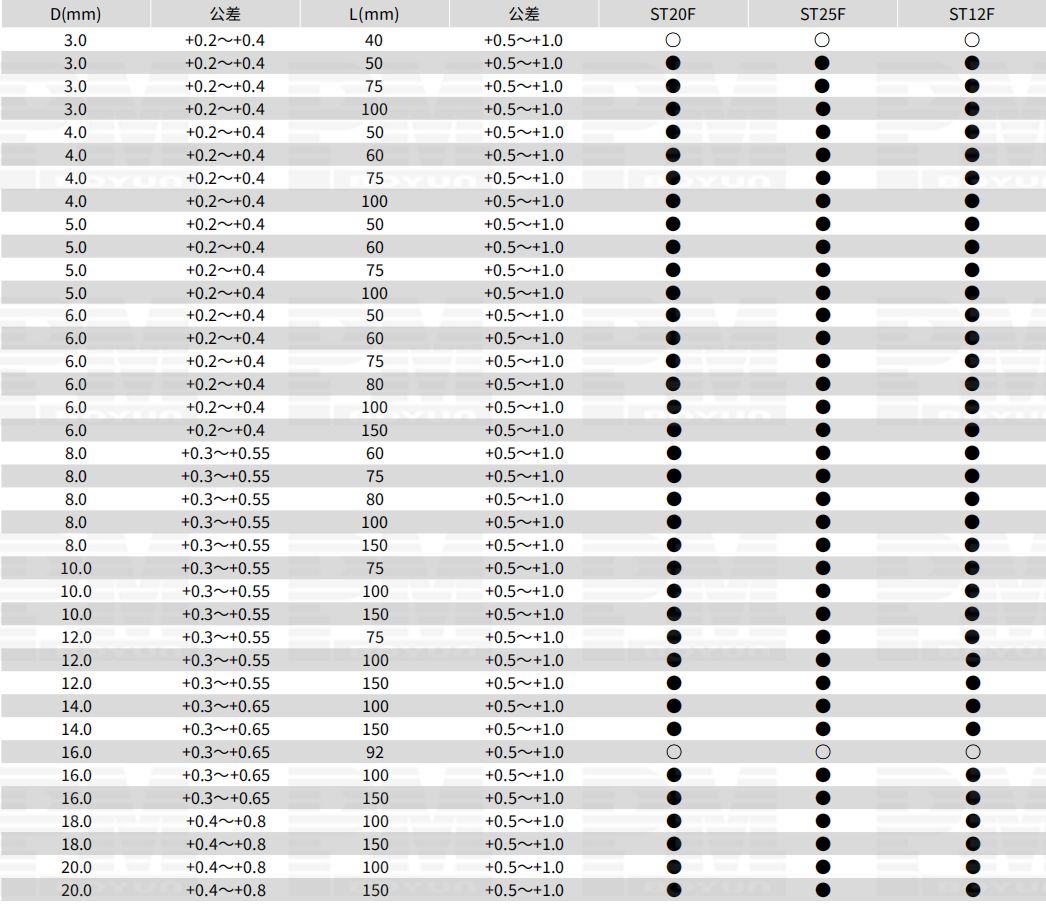

3. Drill Blanks (Chamfered)

4. End Mill Blanks (Chamfered)

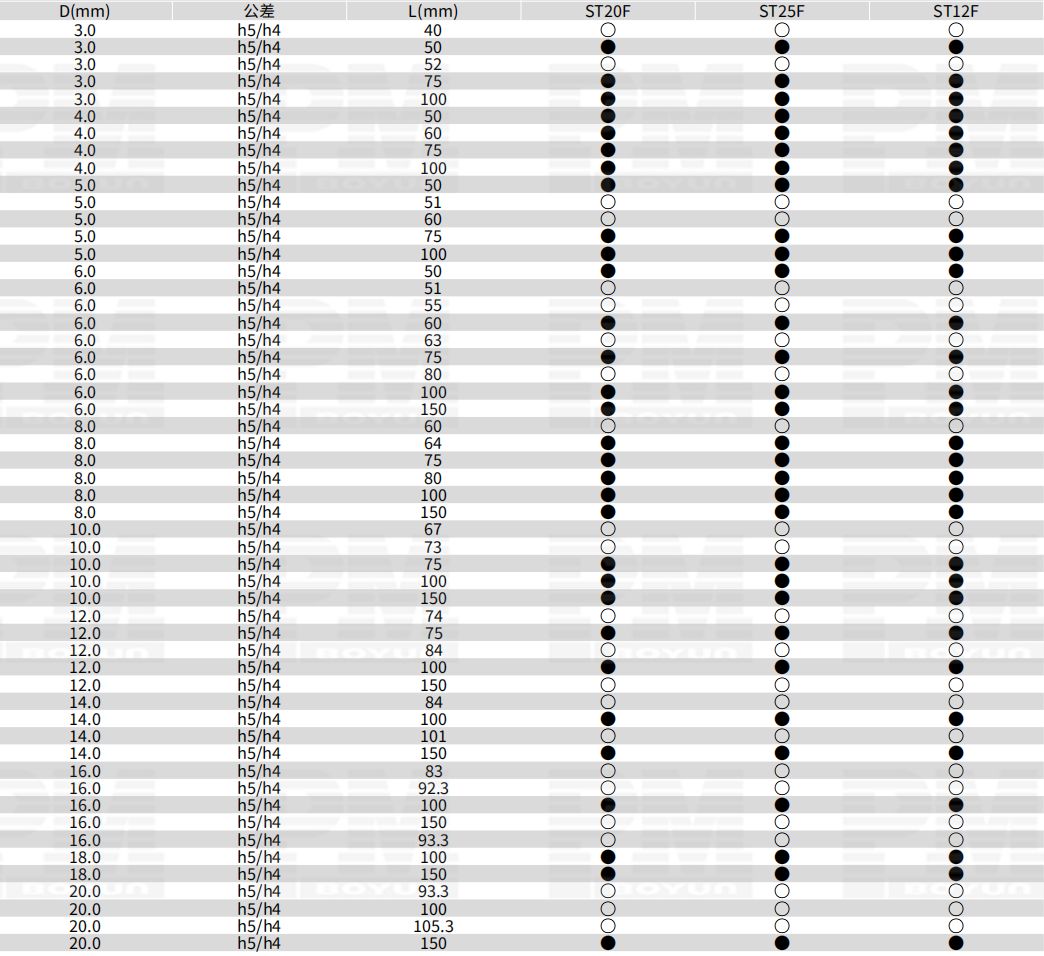

5. Ndodo za Carbide Zokhala ndi Bowo Lozizira Lapakati Lozizira

6. Ndodo za Carbide Zokhala Ndi Mabowo Awiri Owongoka Ozizira

Makhalidwe a Carbide Rod

1. Amapangidwa ndi ufa wapamwamba kwambiri wa tungsten carbide

2. Zida zolondola ndi 10MPa HIP-Sinter sitovu yokhazikika kupanga.

3. Kuuma kwakukulu ndi mphamvu zapamwamba

4. Ubwino Wapadera: Kuuma kofiira, kuvala kugonjetsedwa, kusungunuka kwapamwamba, TRS, kukhazikika kwa mankhwala, kusagwirizana ndi zotsatira, kutsika kwa dilatation coefficient, conduction kutentha ndi conduction magetsi chimodzimodzi ndi chitsulo.

5. Ukadaulo wapadera: kuthamanga kwambiri sintering ya vacuum kutentha kwambiri. Kuchepetsa porosity, kuchepetsa compactness ndi makina katundu. Makalasi osiyanasiyana, mitundu ndi makulidwe.

6. Magiredi osiyanasiyana pakulozera kwanu.

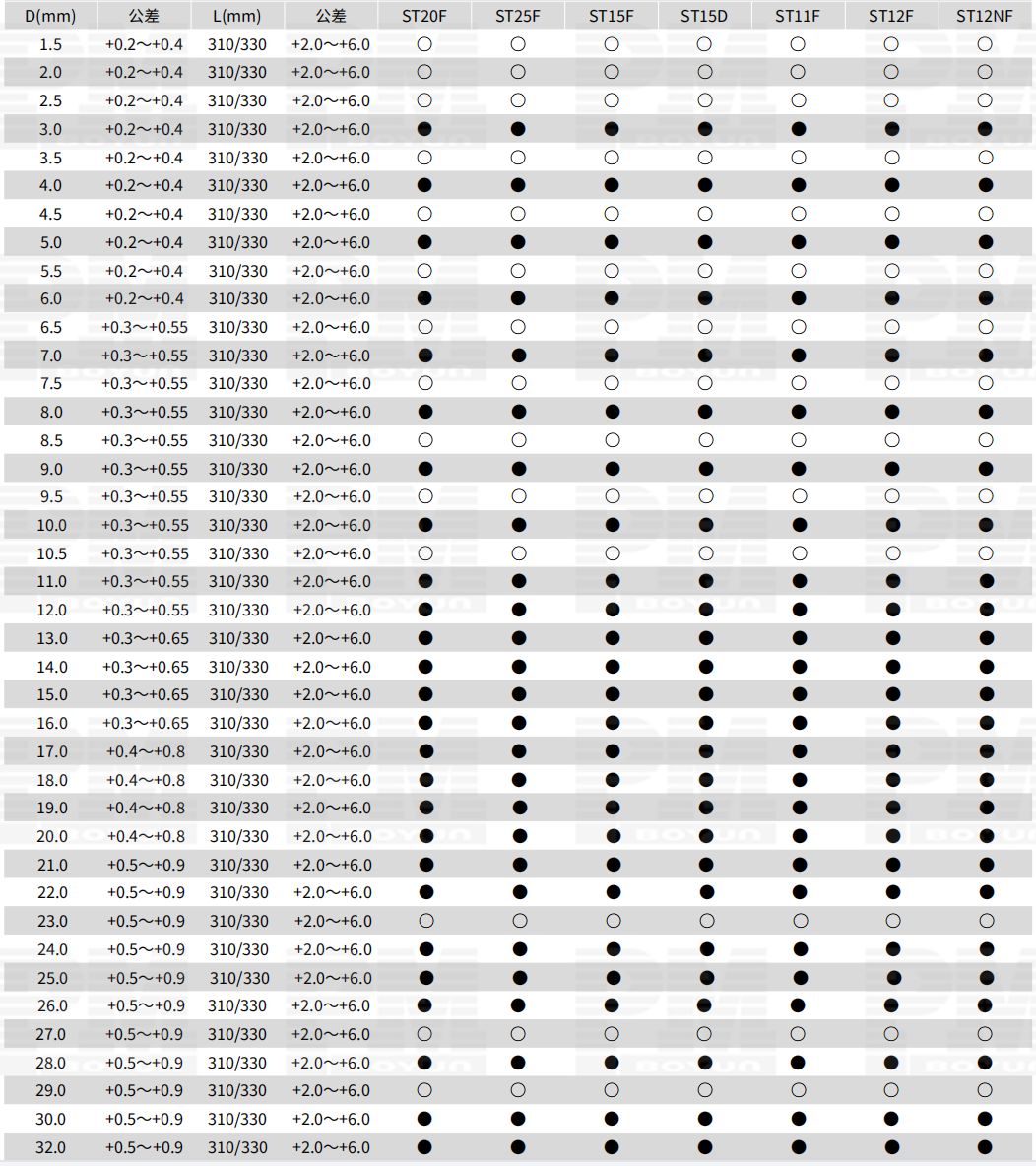

Makulidwe Ofanana

Mndandanda wa Maphunziro

| Chiyambi cha Gulu la Carbide Rods | |||||||

| Gulu | Co % | WC kukula kwambewu | HRA | HV | Kachulukidwe (g/cm³) | Mphamvu yopindika (MPa) | Kulimba kwa Fracture (MNm-3/2) |

| KT10F | 6 | Submicron | 92.9 | 1840 | 14.8 | 3800 | 10 |

| Mtengo wa KT10UF | 6 | zabwino kwambiri | 93.8 | 2040 | 14.7 | 3200 | 9 |

| KT10NF | 6 | nanometer | 94.5 | 2180 | 14.6 | 4000 | 9 |

| Mtengo wa KT10C | 7 | Chabwino | 90.7 | 1480 | 14.7 | 3800 | 12 |

| KT11F | 8 | Submicron | 92.3 | 1720 | 14.6 | 4100 | 10 |

| Mtengo wa KT11UF | 8 | zabwino kwambiri | 93.5 | 1960 | 14.5 | 3000 | 9 |

| KT12F | 9 | zabwino kwambiri | 93.5 | 1960 | 14.4 | 4500 | 10 |

| KT12NF | 9 | nanometer | 94.2 | 2100 | 14.3 | 4800 | 9 |

| Chithunzi cha KT15D | 9 | Submicron | 91.2 | 1520 | 14.4 | 4000 | 13 |

| KT15F | 10 | Submicron | 92.0 | 1670 | 14.3 | 4000 | 11 |

| KT20F | 10 | Submicron | 91.7 | 1620 | 14.4 | 4300 | 11 |

| KT20D | 10 | Submicron | 92.0 | 1670 | 14.3 | 4500 | 11 |

| KT25F | 12 | zabwino kwambiri | 92.4 | 1740 | 14.1 | 5100 | 10 |

| Mtengo wa KT25EF | 12 | zabwino kwambiri | 92.2 | 1700 | 14.1 | 4800 | 10 |

| KT25D | 12 | zabwino kwambiri | 91.5 | 1570 | 14.2 | 4200 | 13 |

| KT37NF | 15 | nanometer | 92.0 | 1670 | 13.8 | 4800 | 10 |

Kuti mudziwe zambiri (MOQ, mtengo, kutumiza) kapena ngati mukufuna ntchito zosinthira makonda, chonde funsani mtengo.